plasticker-News

| 2014-04-03, 06:04 |

|

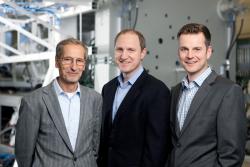

Ettlinger: 30 years of expertise in specialized equipment for polymer processing

Thirty years ago Roderich Ettlinger (left) laid the foundation for the success story of Ettlinger Kunststoffmaschinen GmbH – since 2010 the company has been in the hands of joint Managing Directors Volker Neuber (center) and Thorsten Ettlinger, son of the founder. In 2010, after 27 years as a successful entrepreneur, the company founder transferred his shares to Volker Neuber and his son Thorsten Ettlinger, who have been responsible for all of Ettlinger´s commercial and technical activities ever since. Throughout its history Ettlinger has built up a strong international presence and this will continue in the future. The Managing Directors are taking advantage of the anniversary year to invest again in the Königsbrunn site. "We´re spending an estimated 1.5 million euros on extending our production capacity here. The new building is scheduled to open in the fall, and we´re planning an official customer event to celebrate our thirty years in existence", Neuber reports.  Typical example of a solution tailored to a customer application: an srm 800 injection molding machine (clamping force: 8.000 kN) with an integrated, continuous 'ERF' melt filter that processes contaminated feedstock directly – enabling the client to do away with a complete pelletizing line - (Photos: Ettlinger). Today, thirty years after it first came into being, the one-man firm has been transformed into a global enterprise with local partners in America, Asia, Russia, and Turkey. In 2013 Ettlinger also opened a separate North American subsidiary in Wheaton, IL near Chicago. "Our customers in the US and Canada profit tremendously from Ettlinger North America LP. We´ve experienced a further increase in demand as a result, which is why we´re already making plans to move into bigger premises there too." Volker Neuber then outlines what´s next in the pipeline in Ettlinger´s systematic pursuit of expansion: "In the Asian economic area, where our main focus has traditionally been on Japan, we´re now explicitly targeting other markets, notably China." About Ettlinger Ettlinger Kunststoffmaschinen GmbH was founded in 1983 and is today a global player. The German company has its headquarters in Königsbrunn, not far from Augsburg. Its core competency is the development and manufacture of injection molding machines and high performance melt filters. Ettlinger injection molding machines are optimized for the production of polymer moldings up to 100 kilograms in weight such as plastic pallets, fittings, or manholes. On the melt filtration side Ettlinger makes high performance melt filters for continuous filtration of heavily contaminated feedstock. Contaminants like paper, aluminum, wood, silicones, or high-melting polymer composites can be removed from all standard polymer materials. More information: www.ettlinger.com |

Ettlinger Kunststoffmaschinen GmbH, Königsbrunn, Germany

back to news list back to news list |  back to top back to top |