plasticker-News

| 2008-09-19 |

|

Starlinger launches two new monofilament extrusion lines

|

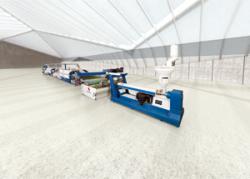

Building on a position of world market leadership in tape and textile yarn extrusion, Starlinger (www.starlinger.com) has launched two new monofilament extrusion lines. The starEX 1500DM – doublehead mono – and the starEX 1500DEM, with two parallel extruders for simultaneous production in two different colours, complement the extrusion technology (Photo) successfully introduced several years ago with Starlinger’s starEX G, M, and TM series. The monofilament fibre market is a growing sector both in quantity and in scope. Trends in modern stadium construction and the demand for sports surfaces that perform regardless of season and weather conditions are greening the market for artificial turf: Improved technology has vastly increased its popularity both as a sports surface and in public and private landscaping. Fibre quality, especially colour uniformity, is particularly critical in the production of artificial grass. Starlinger’s expertise in extrusion and mixing/dosing technology meets the stringent standards for this and other technical applications. Monofilaments are also used in shade nets, anti-hail nets, and other agrotextile applications, as well as in geotextiles and technical textiles, in safety belts and webs, ropes, brushes, and raschel or leno bags, as structural reinforcement in concrete, and for filtration in paper. Starlinger aims to set new standards in economical production of monofilament fibres for these varied applications: The new starEX monofilament lines incorporate significant improvements that reduce power consumption and the cost of operation and maintenance. |

Starlinger & Co. Gesellschaft m.b.H., Vienna, Austria