plasticker-News

| 2012-01-19, 06:06 |

|

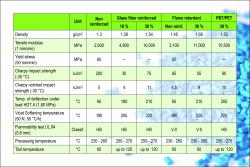

DimeLika Plast: New range of PBT compounds

Table 1: Typical properties and values of selected CompaDur® grades (source: DimeLika Plast GmbH, Brühl, Germany) Alongside industrial-scale chemical companies, the Brühl-based company is one of the first suppliers offering this product group in their portfolio of products manufactured in-house. The CompaDur® product range is available in the usual modifications available on the market. The standard line-up includes non-reinforced, glass-fibre-reinforced, impact-strength-modified and flame-retardant grades, as well as blends of PBT and PET (polyethylene terephthalate). "Products can be customised to meet specific needs, even for small-scale orders. The same goes for special colours required by customers," says Hans-Dieter Voss, Managing Director of DimeLika Plast. PBT is a thermoplastic polymer known for its particularly hard, stiff and strong quality. Due to their excellent flow characteristics, the base material and compounds are ideally suited for the injection-moulding process. Particularly noteworthy is the well-rounded property profile: good slip and wear properties, and extreme toughness even at low temperatures. These products are traditionally used in the motor-vehicle industry for petrol filters, headlamps, sparking-plug connectors and body parts, for example - everywhere materials must meet stringent requirements as regards mechanical properties and heat distortion temperature. Typical product and application sectors for PBT compounds are also found in the electrical and electronics industries. When tested as per the UL 94 plastics flammability standard, the flame-retardant grades achieve a rating of V-0. The UL Mark they bear certifies that they meet the strict safety requirements of the U.S. and Canadian markets. "By making use of the global supply market and a lean corporate structure, we are able to offer our compounds on competitive terms for both quality and price," adds Liborius Flöper, Managing Director of DimeLika Plast. The company offers comprehensive application support services, from the product idea right the way through to production readiness, and develops tailor-made products as needed to meet specific customer requirements. More information: www.dimelikaplast.de |

DimeLika Plast GmbH, Brühl/Baden, Germany

back to news list back to news list |  back to top back to top |