plasticker-News

| 2011-03-01, 06:04 |

|

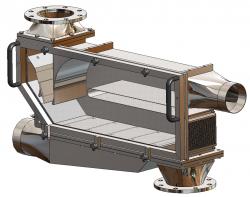

Coperion: Separators now accommodate plastics processors’ needs

With the new horizontal fluidbed separator it is now possible to clean even difficult products efficiently and at low cost; thanks to its low installation height it is also suitable for retrofitment and for use in confined spaces, e.g. underneath silos. Photo: Coperion, Weingarten/Germany With the fluidbed separators it is possible to clean thoroughly and effectively even the most difficult of products, such as brittle, fragile or rubbery bulk materials. The slow cleaning process protects the product and consumes only a minimum of air and energy. They are ideal for use not only in plastics processing installations but also in food processing applications and in other areas of application where the purity of the product is decisive for the manufacturing process, further processing or the quality of the ultimate product. The experts of Coperion’s Competence Center Materials Handling put their comprehensive know-how on bulk materials and cleaning systems into practice and came up with the HFS horizontal fluidbed separator, which, following a programme of intensive performance tests, has now been standardized. A versatile system for the cleaning and dedusting of bulk materials is now available to plant manufacturers and users with immediate effect. The new HFS horizontal fluidbed separators have been designed to meet customers’ ever growing demands for better dust removal, even in cases of application involving relatively small throughputs, while still satisfying high demands in terms of economic efficiency and quality of cleaning. Horizontal separation permits as low an installation height as possible, the minimum being 500 mm. The dosing unit is integrated into the separator, thus saving not only installation height but also the additional costs to the customer of providing his own dosing units on site. Thus the HFS separators are ideal for retrofitment in existing installations. They can be typically installed underneath silos in feed systems supplying pellets to injection moulding machines or extruders, or downstream between compounding extruders and bagging units. The horizontal fluidbed separators do not contain any moving parts and are therefore distinguished by their high reliability and negligible maintenance requirements. They can also be cleaned readily and quickly. As the inlets and outlets are pressureless, the HFS separators are also suitable for use in totally enclosed systems, as in the food industry, for example. With its standardized series of Diverting Counter-flow Elutriators (UGS), Gravity Rotation Separators (SRS) and, now, Horizontal Fluidbed Separators (HFS), Coperion is the only manufacturer to cover the entire range of throughput requirements from 1 to 120 tonnes/hour and offers elutriators and separators for the widest diversity of cleaning standards and applications, says the manufacturer. More information: www.coperion.com |

Coperion GmbH, Stuttgart, Germany

back to news list back to news list |  back to top back to top |