plasticker-News

| 2004-07-05 |

|

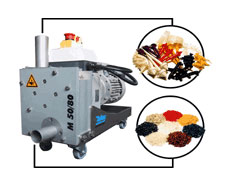

Hellweg: Mini with strong output - Recycling of smallest sprues

During the production of small and smallest units and products, for example for the telecommunication, as handys, or for medical products, as injections, cannulas etc, or for data mediums, as DVDs, very small sprues result at the injection moulding machine. These sprues are often difficult to feed. The advanced mills for incline of the series MRT 50/80 (picture) of Hellweg Maschinenbau GmbH & Co. KG (www.schneidmuehlen.de) make a save grinding of the sprues made of valuable plastics to high graded granulated material possible. The granulated material will directly be added to the new material. Further application fields are the lab sector or the model-making. During the production of small and smallest units and products, for example for the telecommunication, as handys, or for medical products, as injections, cannulas etc, or for data mediums, as DVDs, very small sprues result at the injection moulding machine. These sprues are often difficult to feed. The advanced mills for incline of the series MRT 50/80 (picture) of Hellweg Maschinenbau GmbH & Co. KG (www.schneidmuehlen.de) make a save grinding of the sprues made of valuable plastics to high graded granulated material possible. The granulated material will directly be added to the new material. Further application fields are the lab sector or the model-making.The mills for incline are directly placed at the injection moulding machine. The feeding of the sprues happens over a chute or by a robot into a hopper. Optional the sprues can be exhausted pneumatic through special flexible tubes by vacuum and fed into a collecting bin. Here the compressed air will be controlled from the injection moulding machine by impulse. As a result of this the compressed air only will be fed power saving together with a sprue. The flexible tubes have a very strong and smooth inner surface, so it's guaranteed, that the material can't be damaged caused by abrasion and it can't get stuck. Afterwards the sprues arrive in the cutting chamber and will be ground by hardened rotor- and fixed knifes. Then the material will be pushed through a sieve, which surrounds the cutting chamber. The rotor diameter is only 80 mm at a rotor width of only 50 mm. The driving power is between 0,55 kW and 1,1 kW at a capacity of approx. 1-6 kg/h. The total weight is approx. 55 kg. The machines are fitted with a sound insulating hood made of high-graded steel. This allows a sound level of only approx. 70 dB at a speed of 280 r.p.m. As the rotor and the wearing places in the cutting chamber are made of high-graded steel, the whole machine is nearly maintenance-free. K'2004, Düsseldorf, 20.-27.10.2004, Hall 11, Stand H03 |

Hellweg Maschinenbau GmbH & Co. KG, Roetgen/Germany

back to news list back to news list |  back to top back to top |