|

Economical: Two-Stage Grinding of Valuable Plastic Waste

Hans-Peter Fischer, WEIMA Maschinenbau GmbH

Until now large cutting mills with high drive performances have been used for the single-stage crushing of large and heavy pipes, bulk plastic products etc. This leads to high investment volume, high sound emissions, frequent blade changes, high energy and personnel costs, among other things. On the other hand, two-stage crushing enables plastic processing companies to economically process machine purgings, sprue, rejected items, foils, cables, pipes etc. A practical example: Universal grinders and re-grinders of WEIMA Maschinenbau GmbH, Ilseld/Germany.

The two-stage process opens up a broad spectrum of possible processing materials

Two-stage crushing (Illustration 1) represents the ideal base for economically processing many kinds of plastic waste. The coarse crushing to a grain size of approx. 15 mm is carried out on a single-shaft universal grinder of the production series WLK, which can be used for almost any form of material ranging from foil up to the solid full material block. The material to be ground is then crushed to a grain size of approx. 3-10 mm, which is suitable for re-granulating in a regrinder of the production series NZ (Illustration 2). The two grinding units are arranged optionally behind each other or on top of each other.

Two-stage crushing (Illustration 1) represents the ideal base for economically processing many kinds of plastic waste. The coarse crushing to a grain size of approx. 15 mm is carried out on a single-shaft universal grinder of the production series WLK, which can be used for almost any form of material ranging from foil up to the solid full material block. The material to be ground is then crushed to a grain size of approx. 3-10 mm, which is suitable for re-granulating in a regrinder of the production series NZ (Illustration 2). The two grinding units are arranged optionally behind each other or on top of each other.

The regrinder, which works according to the cutting mill principle, is specially designed for pre-crushed charging material and is therefore designed considerably smaller in comparison to conventional cutting mills. This, from the point of view of the investment required and the spectrum of the field of application, is a clear advantage of the two-stage concept.

The regrinder, which works according to the cutting mill principle, is specially designed for pre-crushed charging material and is therefore designed considerably smaller in comparison to conventional cutting mills. This, from the point of view of the investment required and the spectrum of the field of application, is a clear advantage of the two-stage concept.

The advantages of two-stage crushing mainly take effect in the case of materials for which single-stage crushing is only suitable to a limited extent or not suitable at all:

- Solid material chunks or blocks, e.g. machine purgings

- Bulky deep drawing and injection molding parts, e.g. the inner liner of refrigerators, lorry bumpers

- Thick-walled mould parts, e.g. pallets, plates, tubes, spools

- Tough materials, e.g. foils (particularly pressed or on rolls), carpet remnants

- Metalliferous composite materials, e.g. cables, circuit boards

- Polluted materials or materials containing disturbing substances, e.g. rejects

Universal grinder WLK: Flexible - efficient - strong - quiet

The WLK series distinguishes itself because of a strong drive, high level of stability of the machine frame, powerful transmission and heavy-duty bearings. The speed range (n = 80,,,100) is considerably lower compared to that of conventional cutting mills (n = 400,,,800). Therefore, a clear reduction of the noise level is associated with this. The rotors are stored in enclosed, self-lubricating bearings, which are detached from the frame. Consequently, no material or inherent impurities can penetrate into the bearing housing thereby increasing the serviceable life of the bearings considerably.

As a rule, the machines are driven by an electromotor, which supplies the rotor with power via a hydraulic clutch, drive-belt and transmission. A hydraulic drive can also be used alternatively for larger machines. A single-sided as well as double-sided drive is possible for both drive modes depending on the length of the rotor. The smallest machine of the WLK production series is the WLK 4 with 11 kW drive performance, which is currently the largest of the WLK 30 super Jumbo with 2 x 110 kW. The degree of drive performance needed generally depends on the material to be crushed, the number of cutting tools used and the processing speed required. A higher drive performance is required for the crushing of ABS parts, foils among other things because more work is achieved here in the same unit of time e.g. for the crushing of bottle crates (e.g. PE-HD).

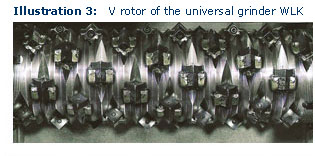

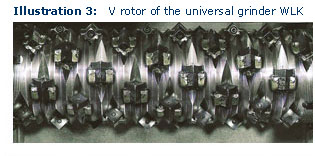

The rotor of the WLK machines is made out of one piece and specially shaped with a patented knife holder (Illustration 3) enabling an exact cut and good chip removal, thereby achieving a low thermal load of the crushed material. Rotors with diameters of 252, 368, 482 and 600 mm are used. A water-cooled rotor is offered for problematic materials that strongly heat up and melt during crushing.

The rotor of the WLK machines is made out of one piece and specially shaped with a patented knife holder (Illustration 3) enabling an exact cut and good chip removal, thereby achieving a low thermal load of the crushed material. Rotors with diameters of 252, 368, 482 and 600 mm are used. A water-cooled rotor is offered for problematic materials that strongly heat up and melt during crushing.

The cutting tools of the WLK are hollow knives sharpened concavely with an edge length of 40, 60 and 80 mm. The knives are made from special knife steel and rotate four times. The life of the knife-edge depends very much on the material to be crushed and the bore of the screen perforation selected, because this influences the residence time of the material in the machine.

The crushing of foils in particular requires an exact die clearance and a large number of knives. The assembly of two - optionally three - rows of knives for the perimeter of the rotor is possible from a rotor diameter of 368 mm. Through this a larger throughput is possible because more knives are "in the cut" at the same time. As a result of the shorter residence time of the material, a higher cutting quality is achieved, which particularly counteracts damage to sensitive materials and simultaneously reduces the dust content.

The clearance of the die can be adjusted by means of a flexible counter knife guide. This so-called 'super-cut' offers reliable crushing of special materials (such as foils) in combination with the knives used here - with specially developed knife tips.

The machines are usually equipped with a conventional screen, in which the choice of the variable screen bore (10 to 100 mm) depends on the further use of the material. Sieves with rectangular screen openings are offered for mere volume reduction by which a fast material residue is obtained. The hydraulic swiveling screen makes it possible to change a screen quickly and simplifies the cleaning and maintenance of the machine.

Fast Feeding of Material with low Deployment of Personnel

The material is fed by a conveyor belt, wheel loader, forklift truck or similar method depending on the machine size, via a funnel that can be operated individually. The funnel is provided with an optional hinged or sliding cover, which is used particularly in the case of high dust formation or in the case of material "dancing" on the rotor. The material to be crushed determines the ideal design here. The funnel and cover are optionally made in a double walled design, by which sound emissions are reduced. When opening, a limit switch with a delay is activated for safety reasons.

The material is fed onto the rotating rotor by means of a "drawer", which presses the material onto the rotor that is controlled depending on the load. In the event of an overload, the machine switches to reverse operation, thereby relieving the drawer. The machine cuts off completely after three reverse operations within a short space of time. The drawer is provided with stripping guides that prevent unwanted material from moving between the drawer and the machine casing. Serrated guides can be optionally added on to the drawer enabling the material to be grasped securely (e.g. for hollow pieces).

Variable Material Extraction for clean Processing

The material is extracted by an endless screw that is driven by an electromotor installed below the screen in the machine frame. Alternatively, a conveyor belt can be used, which is built below the machine and carries material away that falls through the screen. Another alternative is the conventional method of suction followed by sorting in a hydrocyclone or slump. Optionally the entire periphery (conveyor belt, suction etc.) can be switched on or off automatically via a stop & go circuit.

Special Application: Pipe and Section Crushing

The single-shaft grinder WLK R enables the coarse crushing of pipe sections with a diameter of 1,200 mm or up to a length of 3 m depending on the diameter or width of the rotor. The material is fed into the machine from above via a funnel, pressed against a rotating rotor by a hydraulic ram that is controlled depending on the load and crushed there. The newly developed "pipespacer", a special development of the funnel, and the ram integrated in the serrated guide prevent arching and provide a controlled supply of material.

The crusher is available in rotor widths of 1,000 mm to 3,000 mm and with an optional electrical or hydraulic drive of 55 kW to 2 x 150 kW driving power. Different rotor diameters (368 mm to 1,000 mm) are used, which are fitted with rotating cutting crowns (40 x40mm, 60 x60mm, 80 x80mm) that rotate four times. The granule sizes obtained are 20-100 mm depending on the bore of the screen. The throughput achievable is between 200 - 5,000 kg/H depending on the grain size and material.

While the material is fed into the funnel from above with the WLK-R, the single-shaft grinder WPR HK has the horizontal feeding mechanism "sidepass". Pipes of up to 8 m in length and sections with a diameter of up to 800 mm are fed sideways over this to the rotor in batch quantities and pressed against the rotor by means of a hydraulic with controlled pressure and crushed is there. The feed opening can be optionally closed with an integrated telescopic hydraulic manually or automatically.

The coarsely crushed material can be transported via a conveyor belt and crushed from type NZ or SMW to the final grain size (< 8 mm) both by the WLK-R and by the WPR-HK. An NE/FE separator or metal detector is optionally installed above the conveyor belt for separating reject substances.

WEIMA Maschinenbau GmbH

Bustadt 6-10

74360 Ilsfeld, Germany

Phone: +49 (0) 7062 9570-0

Fax: +49 (0) 7062 9570-92

Internet: weima.com |

back to the list

back to the list back to top

back to top

Two-stage crushing (Illustration 1) represents the ideal base for economically processing many kinds of plastic waste. The coarse crushing to a grain size of approx. 15 mm is carried out on a single-shaft universal grinder of the production series WLK, which can be used for almost any form of material ranging from foil up to the solid full material block. The material to be ground is then crushed to a grain size of approx. 3-10 mm, which is suitable for re-granulating in a regrinder of the production series NZ (Illustration 2). The two grinding units are arranged optionally behind each other or on top of each other.

Two-stage crushing (Illustration 1) represents the ideal base for economically processing many kinds of plastic waste. The coarse crushing to a grain size of approx. 15 mm is carried out on a single-shaft universal grinder of the production series WLK, which can be used for almost any form of material ranging from foil up to the solid full material block. The material to be ground is then crushed to a grain size of approx. 3-10 mm, which is suitable for re-granulating in a regrinder of the production series NZ (Illustration 2). The two grinding units are arranged optionally behind each other or on top of each other.

The regrinder, which works according to the cutting mill principle, is specially designed for pre-crushed charging material and is therefore designed considerably smaller in comparison to conventional cutting mills. This, from the point of view of the investment required and the spectrum of the field of application, is a clear advantage of the two-stage concept.

The regrinder, which works according to the cutting mill principle, is specially designed for pre-crushed charging material and is therefore designed considerably smaller in comparison to conventional cutting mills. This, from the point of view of the investment required and the spectrum of the field of application, is a clear advantage of the two-stage concept.

The rotor of the WLK machines is made out of one piece and specially shaped with a patented knife holder (Illustration 3) enabling an exact cut and good chip removal, thereby achieving a low thermal load of the crushed material. Rotors with diameters of 252, 368, 482 and 600 mm are used. A water-cooled rotor is offered for problematic materials that strongly heat up and melt during crushing.

The rotor of the WLK machines is made out of one piece and specially shaped with a patented knife holder (Illustration 3) enabling an exact cut and good chip removal, thereby achieving a low thermal load of the crushed material. Rotors with diameters of 252, 368, 482 and 600 mm are used. A water-cooled rotor is offered for problematic materials that strongly heat up and melt during crushing.