Technical Report 2017-07-05

Content shown in the technical articles are the sole opinion and views of the authors or companies, which are not necessarily congruent to opinion and views of the editors.

|

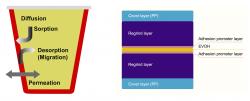

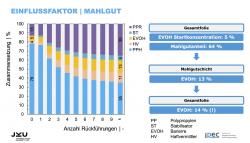

Precision in seven layers Rüdiger Kissinger, motan-colortronic gmbh Worldwide, up to 2.5 billion cups of coffee are drunk every day. Much of this is prepared from coffee powder capsule portions in coffee machines. Due to the necessary oxygen barrier to prevent ageing of the coffee due to oxidation, these capsule portions consist of either aluminium or a plastic composite foil with an integrated oxygen barrier. Since 2015, the latter have been produced by the “Greiner Packaging” in Kremsmünster, Austria (Fig.1). For this purpose, a sustainable production concept was developed together with the peripheral equipment manufacturer motan and the Austrian agent Luger. With this concept, the punching waste left over after punching out the deep-drawn capsule bodies is completely fed back into the 7 layer extrusion line in accordance with all quality limits.  Fig.1: Capsules made of a 7-layer composite foil are the modern way of storing coffee in portions. The film combines barrier properties and recyclability (Photo: Greiner Packaging)  Fig. 2: The 7 layer barrier foil which comes out of the extrusion machine runs directly into a multi cavity deep drawing and punching machine. The remaining punched frame and any bad parts produced are then fed directly into a cutting mill (in the background at the end of the machine) and fed back into the production line from there. (Photo: Author) As mentioned at the beginning, the portion containers consist either of aluminium or plastic, both made of deep-drawn foils. However, without evaluating which is the better packaging solution, there is a significant difference between the two alternatives. Whereas an aluminium foil is a good barrier against almost all external influences, there are only very few plastics which are gas tight and aroma tight. EVOH, an ethylene vinyl alcohol copolymer, offers the best barrier properties against both oxygen and steam. It is just as water tight as an LDPE layer which is 10,000 times as thick. As it is comparatively expensive, it is used centrally as a thin barrier layer within a compound foil together with other plastics. At Greiner Packaging in Kremsmünster, Upper Austria, a 7 layer compound foil is used top produce coffee capsules. (See fact box “Multi layer foil for coffee capsules”)  Fig. 3: A 5 aggregate extruder is used to produce the 7 layer barrier foil. The central extruder is responsible for 70 per cent of the foil in the form of the recycling percentage. It is flanked by the extruders for the barrier layer and the adhesion promoter layers. On a production level arranged above this, the extruders for the PP cover layers are arranged, which are connected to the feed block via vertical smelting lines (visible in the background). (Photo: Author) As the cups of the coffee capsules are produced from the compound foil by deep drawing and punching, more than 50 per cent of the film remains as a punched frame. As this quantity of waste could not have been disposed of logistically or economically due to the projected mass production, Greiner Packaging developed a concept for complete recycling of the punching waste during ongoing production together with the long term system partners, the German motan group, a manufacturer of peripheral systems, and Luger GmbH from Austria, as motan project planners and plant fitters and the extrusion technology supplier. For this purpose, the multi layer foil to be produced must be adapted in such a way that up to 60 per cent of it can consist of the regrind of the original foil. The punched frame and waste parts are ejected directly from the deep-drawing machine and fed into a mill (Fig. 2).  Fig. 4: The 7 layer foil machine is constructed in three functional levels on top of each other. On the lowest level (not visible here) there are three extruders (see Fig. 3), on level two there are two extruders for the cover layers, on the top level the dosing units to supply the extruders situated below (Photo: Author)  Fig. 5: Central mixing station to supply the “regrind extruder”. In this, four material components come together (regrind from the silo or from the BigBag, stabiliser for the adhesion promoter and new PP material) which are added from the gravimetric dosing units on the third level. (Photo: Author) Dosing precision lies in the detail As mentioned above, most of the material throughput is from the regrind layers, which are supplied via gravimetric dosing units and a downstream mixing system due to possible fluctuations in the bulk density. Comment by Helmut Reckziegel, Head of Business Unit Capsules: “In this regard it is worth mentioning that the regrind fed back into the multi layer foil as filler material consists of the 7 layer foil and is therefore composed of the five different viscosity materials which this contains. It was our joint objective to achieve stable mixing and flow properties for this 5 material mixture. An unstable material composition, whether due to fluctuating bulk density or a change in material proportions, leads to reductions in quality of the extrudate, in particular when seven layers have to harmonise with each other. As we wanted to install a control option for this, we provided for the addition of virgin PP material to the regrind. Therefore, the continual enrichment of the concentrations of the percentage of EVOH and of the adhesion promoter in the total foil, triggered by the return of the stamping grid, can be stabilised at 14 and 12 per cent respectively and consequently the melt flow index.” (Fig. 6)  Fig. 6: Factors of influence on the composition of the regrind fed back into the cycle. (Graphic: Greiner Packaging) All other material percentages are added volumetrically as virgin material in constant quality. The throughput quantities for the barrier material and the adhesion promoter are a maximum of 60 kg/hr. The throughput of PP layers, which are additionally mixed with a white or brown colour master batch, is somewhat more, at approx. 110 kg/hr (see Fig.1).  Fig. 7: All functions and setting data of the complex conveying and dosing machine are controlled by CONTROLnet, an integrated control concept for the operation, monitoring and management of all steps of raw material handling and connnected to the motan master computer system via LINKnet 2.0. (Photo: Author) All machine components are activated and operated via the remote controlled electronic modules specifically developed by motan for this purpose. These are GRAVInet for gravimetric dosing units and VOLUnet for volumetric dosing units. They are connected to a ControlNet of the central machine control via Ethernet or TCP/IP. This can be extended up to LINKnet, a comprehensive plant management system (Fig.7). It is thus possible with Linknet 2.0 to collect and log the process sequences and application data and to operate all connected controls up to device level. All motan controls with communication capability can be connected. Batch tracking is therefore continuously possible. Success due to many years of proven partnership  Fig. 8: Helmut Reckziegel, Head of Business Unit Capsules at Greiner Packaging and Horst Bar, the responsible Project Manager at Luger GesmbH look back on 40 years of co-operation with motan. (Photo: Author) Info box: Multi layer foil coffee portion capsules What requirements? Coffee portion capsules made of foils must form a barrier against the ingress of steam, atmospheric oxygen and other unwanted substances as well as against the effects of UV radiation. The barrier must also protect against the escape of constituents such as aromas and moisture. At the same time, the foil cups can also provide protection against defined mechanical stresses during transport and storage. Which foil structure? A 7 layer compound foil is used for the coffee capsules. Its central layer consists of EVOH (ethylene vinyl alcohol co polymer). It forms the oxygen barrier and is embedded on both sides via adhesion promoter layers of recycling material (punching waste). Coloured polypropylene layers (homo polymer and co polymer) are additionally applied as cover layers. motan gmbh Otto-Hahn-Straße 14 Phone: +49 (0) 6175 792 167 Internet: www.motan.com |

back to the list back to the list |  back to top back to top |