plasticker-News

| 2010-05-14 |

|

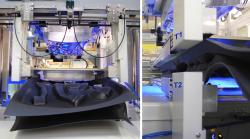

ILLIG: Thermoformed, Soft Air Ducts Are Picking Up Speed

Thermoformed, very lightweight and flexible vehicle air ducts in sophisticated 3D-geometry made from XLPE foam: Mass-produced by Intecsa in the twinsheet method meanwhile even on two ILLIG UAR 155g thermoformers.  From draw-in into the machine through to discharge of formed and punched twinsheet air ducts from the forming station (left), the webs are exactly guided by means of two height-adjustable servo driven transport devices (T1, T2 on right photo) equipped with toothed chains. Photos: ILLIG/Intecsa Beneficial properties – customized thermoforming technology A duct made from PE foam (density approx. 70 to 80 kg/m³, subject to application) is not only substantially more lightweight than a duct made from solid PP (density about 0.9 g/cm³ and/or 900 kg/m³), among other properties, due to its structure heat conductivity of foam is much lower and dampening of sound propagation is higher. In this way the low heat conductivity and heat capacity of foam minimize possible formation of condensation water in the air duct after air condition switch off. Installed, e.g. in the B-column of a vehicle, and supplied with 2.7 m/s air speed, reduction of the sound pressure level amounts to at least 3 dB(A) due to improved acoustic dampening of the thermoformed, soft duct (foam density 80 kg/m³, d = 4 mm). This means the intensity of the sound source is reduced by 50 % compared to blow-molded hard ducts. High elasticity and good resilience of the ducts provide further benefits such as easy application options and reduction of squeaking and rattling even with smallest installation space available. And since XLPE foam ducts also weigh up to 65 % less than comparable PP hard ducts, they additionally meet the general demand for weight reduction in today´s automotive engineering very well. Chemically cross-linked XLPE foams used by Intecsa for the production of flexible air ducts can be reliably thermoformed. Process-controlled UAR 155g thermoformers of the newest generation meet the demands for twinsheet thermoforming in a very efficient way. The servo motor drives employed for precise and fast movements with high repeat accuracy provide the basis for a reliable process. In twinsheet forming the process steps heating, forming and punching are performed in the same station. Two transport devices, arranged above each other and adjustable in distance, feed the XLPE webs to the machine. Film thickness 3 to 4 mm. The material is supplied from roll stock by two material roll stands. In the forming station with the tool halves fixed on upper and lower table the two material webs are heated up to max. 200 °C surface temperature each by means of height adjustable heaters. Subsequently, the heaters move out of the forming station very fast – travel time below 3 s – in order to minimize cooling down of the material until start of the forming process. Consequently, the servo drives for upper and lower tool table are especially designed for very high speeds of up to 500 mm/s and this even applies for tools with a weight of up to 1 t per tool table. There is still enormous potential for development A major advantage provided by thermoforming compared to extrusion blow molding is the fact that on the large-area tools (UAR 155g forming area max. 1.450 mm x 1.200 mm) it is possible to manufacture several products at the same time in one work step and, moreover, the products can be of different size and geometry. This means short cycle times per air duct. In this way air ducts made from foamed materials are competitive with blow-molded hard ducts made from PP granulate also with respect to costs – manufacturing costs per duct are comparable. Meanwhile air ducts made from XLPE foams have found their way into several European car manufacturers´ mass production of some models. They are employed in dashboards, center consoles and B-columns and also in the roof area. However, application in the broad range of vehicle manufacturing is only at its beginning. Intecsa count on this future and meanwhile they have been using the two twinsheet thermoformers to full capacity for production of these air ducts for vehicle mass application. So the number of multi-cavity tools for different duct geometries developed and built together with the ILLIG tool shop has been increasing already ten in Armiñon. With still increasing demand for thermoformed air ducts made from XLPE foam by vehicle manufacturers it is very likely that a third UAR thermoforming line can soon be found on Intecsa´s investment list. More Information: www.illig.de, www.hutchinsonworldwide.com |

ILLIG Maschinenbau GmbH & Co. KG, Heilbronn, Germany

back to news list back to news list |  back to top back to top |