Technical Report 2010-07-23

Content shown in the technical articles are the sole opinion and views of the authors or companies, which are not necessarily congruent to opinion and views of the editors.

|

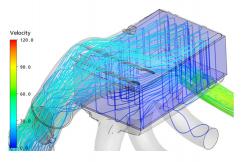

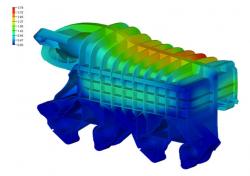

Intake manifolds with integrated charge air coolers increase engine responsiveness Marco Barbolini, Röchling Automotive AG & Co. KG Intake manifolds with integrated charge air coolers increase engine responsiveness, because air volume is reduced by over 40 percent. Further the integration cuts over 20 percent parts, weight and costs. Failure probability is shrinking also. Tightness, even air distribution, temperature and bursting pressure durability as well as different heat elongation of metal and plastic turned out to be a big challenge for Röchling Automotive´s engineering and manufacturing.  Konventionelle Ansaugstrecke mit Ladeluftrohren, heiße und kalte Seite, sowie weit abgesetztem Ladeluftkühler  Neue Topologie der Ansaugstrecke mit Ladeluftkühler in Saugrohr integriert spart 40 Prozent Luftvolumen und Bauraum sowie 20 Prozent an Teilen, Gewicht und Kosten Even air distribution is optimized with powerful CFD software when an intake manifold is designed. Computational Fluid Dynamics processing is yet manifoldly more complex with an integrated heat exchanger than for a simple intake manifold. At the same time the request for balanced air distribution is even higher. It is not only about even air volume but also even air temperature for each cylinder. No matter which temperature prevails in ambient air, engine and coolant. The high temperatures are on par with high pressures, yet both of them are not steady, but varying according to changing engine power output. Röchling Automotive´s engineers simulated the dynamic loads with elaborate processing models for the intake manifold as well as for the heat exchanger. Pressure change tests proved the design. "At the and of the day, we had verified all extreme scenarios. Without weight penalty," Barbolini remembers. "This shows how much you can achieve with intelligent geometry. At each point enforcement and thinning follow as accurately as possible the load vectors there. Exactly as in nature, for example in birds bones." The rapidly changing ambient and operating conditions add to the stress of the plastic housing and the aluminium heat exchanger due to their different, material specific heat elongation. "We compensate for the distinct elongation coefficients largely with an air gap," says Barbolini. "Yet, the problem remains on the contact areas. After this has also turned out to be feasible, the trend towards this basic design is gaining momentum everywhere. This was a real breakthrough." Röchling Automotive AG & Co. KG Richard-Wagner Str. 9 Phone: +49 (0) 621 44055 0 Internet: www.roechling.de |

back to the list back to the list |  back to top back to top |