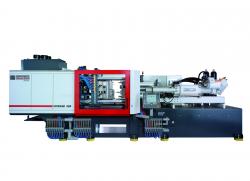

VITESSE 250: New hybrid high-performance injection molding machine with a clamping force of 2,500 kN

About Vitop

Vitop is part of the Smurfit Kappa group and is the world leading manufacturer of taps and connection systems for modern Bag-in-Box beverage packaging. The two new VITESSE will be used for the production of a tap for such beverage packaging. One VITESSE 250 is fitted with an injection unit of international size 1,000 and produces the body of the tap, while the other machine is fitted with an injection unit of international size 1,650 and produces the connector for linking the tap with the respective package. This allows the beverage to be ideally conserved prior to and after being opened.

The VITESSE takes its name from the French word for “speed”, the most remarkable feature of the new Ferromatik Milacron machine series. The electric screw drive allows for parallel functions, resulting in extremely short cycle times. The stability required for the machine’s excellent dynamics is provided by a reinforced base with linear guides. The machine includes a high-performance barrier screw with a mixing head and an L/D of 25:1 for optimal melt quality and even color distribution.

The VITESSE series comes in clamping force sizes of 2,000, 3,000, 4,000 and 5,000 kN, and can be equipped with injection units of international sizes 1,000, 1,650, 2,650 and 4,400. In total ten combinations are available. Due to its high demand the series is being constantly extended and is also optionally available in intermediate sizes with a higher clamping force or with larger injection units up to international size 10,100. |

back to news list

back to news list back to top

back to top

back to news list

back to news list back to top

back to top