plasticker-News

| 2010-02-24 |

|

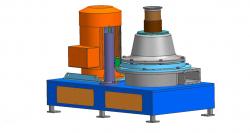

Pallmann: Pulverizing, Coating, Mixing, and Defiberizing with the ConoMill® type PLK

|

The PALLMANN, ConoMill®, type PLK is used for pulverizing, mixing, homogenizing, coating and defiberizing of various materials in the food,- chemical,- mineral,- building material and plastic industry. Possible materials are, for example pigments, paints and resins, pharmaceutical product, primary products for agriculture, plastics, fillers 8powdery or fibrous), gypsum and lime stone, grains, legumes, sugar and spices. There are various ways to dose the feed material into the mill according to the re-quirements, such as vibratory feeder, feed screw or a rotary air lock. The rotor is aligned vertically and together with the stator they form a cone-shaped grinding chamber. This geometrical arrangement allows the grinding gap to be easily set by raising or lowering the stator. Size reduction or conditioning occurs between the impact edge of the rotor and the wear resistant grinding path. The degree of fineness or conditioning is controlled by the grinding gap, circumferential speed of the impact edge of the rotor, volume of air, rotor type as well as the type of grinding path, thereby resulting in preferred combinations for pulverizing, mixing, dry grinding and coating. Very often there is no requirement for a sifter to control the upper particle size. A blower suctions the product out of the mill and into either a cyclone or filter separator. Upon product change or exchange of the rotor, the upper side of the monoblock housing is easily lifted by means of an electric gear motor. Afterwards it is swivelled to the side and turned 180° around its horizontal axle. The grinding chamber and the conical rotor are now easy to access, clean or to exchange.The PALLMANN ConoMill®, type PLK is available in a pressure shock-resistant design up to 10 bar for dust explosive type materials. The rotors and grinding paths can be made of wear resistant ceramic specially designed for abrasive hard materials and for an iron free grinding in the food industry. Also for the food or chemical industries the mill is available in stainless steel and/or GMP compliant versions. More Information: www.pallmann.eu Powtech 2010, 27.4.-29.4.2010, Nuremberg, Hall 7, Stand 547 |

Pallmann Maschinenfabrik GmbH & Co. KG, Zweibrücken, Germany

back to news list back to news list |  back to top back to top |