plasticker-News

| 2010-10-25 |

|

Billion + Motzener: New level in 2 components technique for rubber/thermoplastics

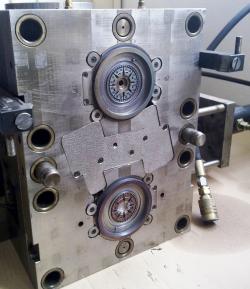

At K 2010 Billion shows how a two components gastight sealing membrane can be manufactured in a fully integrated single operation process At K 2010 Billion shows how a two components gastight sealing membrane can be manufactured in a fully integrated single operation process Billion has developed in cooperation with Motzener Kunststoff- und Gummiverarbeitung GmbH a rubber/thermoplastics application. The Billion Select H150/260-150T will produce with a multi-injection process a gastight membrane, resistant to ozone dedicated to the gas appliances industry.  Sealing membrane in PA 6.12 and Rubber with thin wall parts, resistant to ozone, gastight and in a demanding geometry. According to Motzner, most plastics processors still use 2 stage-processes for such type of parts: 1.) One machine for the production of the body in thermoplast material (hard component), then transfer on a rubber machine, 2.) Overmoulding, and finally vulcanisation of the Elastomer (soft component). Motzener have chosen here the advantage of a real single stage process in one production cell. One advantage is, that contrary to conventional vulcanisation process, no griping agent is here needed. The Billion Select machine is fitted with 3-Zone-plasticization units available on standard, with adapted screw geometry for Polyamide-Components (Vestamid from Evonik) and Rubber material (Kraiburg). Both screws benefits from a special surface treatment and are protected against abrasion. The Billion 3-zone rubber screw maximizes the protection of the material in the barrel, thanks to reduced compression and shear stress. The basic body in PA weighs 3g, as well as the rubber part, with a complete cycle time of approx. 60s The translation of the plastic part onto the rubber side is carried out thanks to an Index plate. The vulcanization takes place in the mould. The Motzener experts have produced so far with 2-components technology more than 150 millions sealing disks for oil filled capacitors with a cycle time less than 60s. Perfect combination of machine and mould The process runs in a completely integrated system, thanks to the DIXIT 3 control system of the Select H150/260-150T which guarantees the complete control of the various movements. For the mould, the movements concerned are: core programmes, vacuum pump, hot runner system, turntable, and temperature controller. The coordination of all steps in the process can be transparently determined and freely programmed. Production in single operations safe cost and time Thanks to the centralised control, the demanding one step process runs in a better and quicker way than it used to. Most important thing is the process reliability: Security is important in the final application field of the membrane, as it must be gastight. In the classical one component process, some thermal damages on material occurred some time due to vulcanisation time and temperature. According to Thomas Koenig, General Manager at Motzener, from an injection point of view, this rubber part is very demanding, taking into account the extremely thin wall thickness, as well as the complicated geometry of the part. For Motzener, in order to switch to an actual single-step process, it was necessary to develop a 2-components process able to produce series, even for complicated geometry with very thin wall rubber components, and to identify the suitable materials.  Full-electric Billion Select H150/260-150T for enery efficient rubber overmoulding. (all photos by Billion) A special „Motzener-Process“ for rubber processing with energy and material efficiency at a new level In order to manufacture high-quality multi-material parts in mass production, the Motzener process was optimized several times. It was important that the parameters to be set through the machine, like temperature, heating time, air and mechanical ejectors, match the injection parameters. In addition, the special materials used for the body and the seal in terms of adherence, play an essential role with regards to the functionality and the quality of the parts. This concept launches a real step forward in the association of full electric injection technologies, energy efficiency and rubber processing. Thomas Koenig: „On the basis of our long-time experience in vulcanization, we are convinced that the demanding, but very efficient 2-components rubber injection as single process is the solution of the future. Compared to a separated solution for each component of the process, the integrated „single process” with accuracy of an electric injection moulding machine brings really more transparency in the process and thereby less scrap and higher quality. With this configuration, relevant usual costs for a 2-Stage process like floor space, stock and logistics disappear. The part developed in collaboration with a well known manufacturer of gas security appliances industry complies with the specifications of the DVGW (Deutscher Verein des Gas- und Wasserfaches e.V.). erteilt. More Information: www.billion.fr, www.plastics-rubber.net, www.hahnautomation.com K 2010, 27.10.–3.11.2010, Düsseldorf, Hall 15, Stand B24 |

Billion S.A.S., Bellignat, France

back to news list back to news list |  back to top back to top |