plasticker-News

| 2008-09-29 |

|

Automatik Plastics Machinery: Pelletizing specialist under a new name at Fakuma

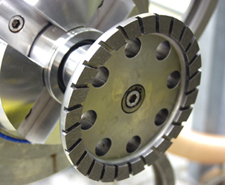

The former Rieter Automatik GmbH will celebrate its new name "Automatik Plastics Machinery GmbH" (www.automatikgroup.com) at Fakuma 2008. Its exhibit, located at Stand 6202 in Hall A6, will provide a working demonstration of the SPHERO® 70 underwater pelletizing system along with the OPTOcontrol operating control system. As a special highlight, Automatik will display its newly designed PRIMO Plus strand pelletizer with quick-change cutting head. The former Rieter Automatik GmbH will celebrate its new name "Automatik Plastics Machinery GmbH" (www.automatikgroup.com) at Fakuma 2008. Its exhibit, located at Stand 6202 in Hall A6, will provide a working demonstration of the SPHERO® 70 underwater pelletizing system along with the OPTOcontrol operating control system. As a special highlight, Automatik will display its newly designed PRIMO Plus strand pelletizer with quick-change cutting head.Quick and easy cutting head changes for maximum machine availability in compounding applications The new PRIMO Plus strand pelletizer family with optional quick-change cutting head was developed to meet the most demanding production needs for compounds and blends, at throughput rates of up to 5,000 kg/h. A wide range of options is available, allowing the basic platform to be optimally and cost effectively tailored to exact application requirements. The innovative quick-change cutting head feature is ideal where frequent product changes are required. With just a few knobs, the cutting head can be loosened and easily switched with a stand-by cutting head. Within a very short time, production can be resumed, and the removed cutting head can be serviced or changed without effecting production. This feature thus increases machine availability and lowers production costs. Highlights of the new PRIMO Plus family at a glance: • Best product quality at the lowest production cost • High flexibility for quick, reliable product changeovers • Rapid cutting head changes • Maximum machine availability at low total cost of ownership Superior product quality and low production costs in underwater pelletizing The SPHERO® underwater pelletizing system is specifically designed for thermoplastics. A unique knife head design and optimized flow conditions within the cutting chamber ensure perfectly spherical pellets which are ideally suited for further processing. The extremely flexible system has proven itself in demanding production environments, providing throughput rates of up to 18,000 kg/h with minimal space requirements. Through axial movement of the motor shaft, the main drive motor continuously regrinds the knife edges during operation, increasing equipment availability and thus reducing costs. A new built-in regrinding feature is now available for all SPHERO® models as an order option or upgrade kit. It enables the die plate to be reground without disassembly, thus saving the time and cost of removing and reinstalling the die plate. Additional benefits of SPHERO®: • Low energy consumption • Quick product change, with very short cleaning and start-up cycle times • Unrivaled cutting tool lifespan OPTOcontrol operating control system: For transparency in production OPTOcontrol facilitates the simplified monitoring and systematic optimization of pelletizing and upstream extrusion processes. It integrates the process controls for the various components into one common control system, running on a standard PC and monitor. The security system uses password-protected user levels to restrict access to sensitive data. The monitor provides a clear and easy-to-understand display of operating and energy data, process settings, and any alarms or events, bringing transparency and repeatability to the production process. All process data are archived along with detailed error reports, helping to identify weaknesses and opportunities for improvement in production as well as providing an essential resource for quality management. Photo: SPHERO® - Grinding Device FAKUMA 2008, Friedrichshafen, 14.-18. October 2008, Hall A6, Stand 6202 |

Automatik Plastics Machinery GmbH, Grossostheim, Germany

back to news list back to news list |  back to top back to top |