plasticker-News

| 2025-10-30, 12:54 |

|

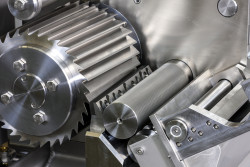

Maag: New Cutter Bar for Strand Pelletizers - High Hardness and Extended Service Life Solution for Fiber-Reinforced Plastics

|

When strand pelletizing fiber-reinforced plastics (FRP Compounds), the cutting tools are subject to intense abrasive wear. To reduce the resulting wear, Maag has developed the new cutter bar "Duration". It is based on a novel material called "VS23", which was specifically designed for this demanding application. Previously, Maag offered cutting tools in the variants Tungsten Carbide (HM), Ceramic (CE), and Polycrystalline Diamond (PCD)-tipped. When processing abrasive, fiber-filled polymers, HM and CE tools typically only achieve a service life of around 100 operating hours. Furthermore, ceramic cutting edges are prone to breakage, which leads to frequent tool changes and thus to production interruptions. Although PCD tools have a significantly longer lifespan due to their diamond-coated surface, they incur up to five times higher tool costs. The "VS23" material, newly introduced by Maag, is intended to increase the hardness of the cutter bar by up to 70 percent and significantly reduce wear. According to the manufacturer, internal studies and practical tests show that the service life is extended by five to nine times compared to conventional HM cutting edges. This makes the new cutter bar a cost-effective alternative to diamond-tipped tools, without their high investment costs. With the introduction of the "Duration" cutter bar, Maag is expanding its product portfolio with an economical solution for use in strand pelletizers, specifically designed for processing highly abrasive, fiber-reinforced plastics. More information: maag.com |

Maag Group, Oberglatt, Switzerland

back to news list back to news list |  back to top back to top |