plasticker-News

| 2011-03-07, 06:06 |

|

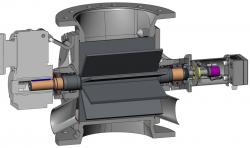

Coperion: RotorCheck protects both rotary valve and product

The compactly built RotorCheck system protects the rotary valve against mechanical damage and the conveyed material against metallic contamination. Cutaway diagram: Coperion, Weingarten/Germany In all these cases, RotorCheck not only prevents serious damage to the rotary valve itself but also protects the product, which in most cases is conveyed by a pneumatic conveying system, against contamination by metallic particles (abraded metal). It is precisely this aspect of product purity – always at the top of the list of priorities in baby food production – that has now become so important in the plastics industry, too. Typical examples are the handling of polycarbonate pellets for the production of CDs and the handling of insulating polymers for high tension cables. Highly reliable in operation – no false alarms With the RotorCheck system, the rotor is insulated against the housing and subjected to an electric charge. Any metallic contact between the rotor and the housing causes a drop in voltage, which is detected by the system and signalled by an alarm. The contact monitoring device featured by the RotorCheck differs essentially from existing systems in that the new, fully system-integrated evaluation logic circuit serves to set the product parameters – the moisture content, for example – of the conveyed material. As the evaluation logic circuit operates in conjunction with a highly efficient microcontroller, false alarms are largely excluded and the RotorCheck operates with a high degree of reliability. Also contributing to this high degree of reliability is the electronic self-monitoring system: any interruption in the circuit – caused by a broken cable, for example – is signalled by an alarm. It goes without saying that RotorCheck is also suitable for systems designed for use in hazardous locations. Since the interior of the rotary valve is in such cases frequently categorized as ATEX Zone 20, the part of the system within of the rotary valve interior is rated to meet the requirements of category II 1D, says the manufacturer. More information: www.coperion.com |

Coperion GmbH, Stuttgart, Germany

back to news list back to news list |  back to top back to top |