plasticker-News

| 2009-03-12 |

|

Kreyenborg: Infrared Drum IRD for crystallizing and drying of PET flakes to Ireland’s Foamalite

|

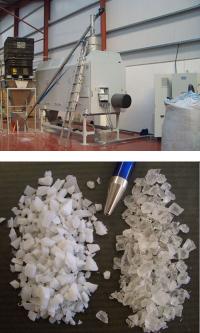

The German machine supplier Kreyenborg Plant Technology (www.kreyenborg.de, www.kreyenborg-group.de) has delivered an energy efficient Infrared Drum IRD for the crystallizing and drying of PET flakes that is installed in a new multi million Euro installation of a complete sheet extrusion line at Ireland’s specialist sheet extruder Foamalite Ltd. Loch Gowna site (www.foamalite.ie). “Especially the speed and the efficiency of this system convinced us”, said Philip Jones, project manager of Foamalite. Using the infrared technology it is possible to process the material in minutes rather than hours. Owing to the fact that the infrared radiation directly enters into the material and heats it from the inside, additionally very low energy is required. Two essential advantages compared with conventional systems. Crystallization of thick-walled PET Flakes The Infrared Drum IRD is applied for the in house recycling at Foamalite. Thereby the crystallization of the very thick-walled PET Flakes, which are generated with sheet extrusion, is particularly sophisticated. “Here the Kreyenborg Infrared Drum IRD is the ideal solution and provides for all future contingencies”, so Philip Jones. By means of the flexibility of the machine concept in future also PET bottle flakes may be predried and crystallized. Meanwhile the Kreyenborg Infrared Drum IRD is applied worldwide. Drying and crystallization of PET are the special focus in the application. However this system is also best suited for the processing of other plastics and bulk goods. Photo, above: Infrared Drum at Foamalite Photo, below: With Infrared Drum processed material |

Kreyenborg Plant Technology GmbH & Co. KG, Senden, Germany

back to news list back to news list |  back to top back to top |