plasticker-News

| 2025-11-06, 09:23 |

|

Lindner: New Solvent-Based Cleaning Process “Flexloop” – Cooperation with Procter & Gamble

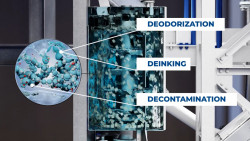

Flexloop is the name of the new mechanical recycling technology that Lindner presented to recyclers at K 2025 together with P&G. Using a solvent-based extraction process, the company says polymer chains are reliably freed from impurities (NIAS), odors, adhesives, and printing inks – and this with consistent purity, enabling recyclates to be used even for sensitive packaging applications such as in the cosmetics or hygiene sectors - (Image: Lindner Recyclingtech). The technology originated from a development partnership between Lindner and Procter & Gamble, which began at K 2022. Following an intensive development phase, Lindner acquired the exclusive license rights to the process developed by P&G. Both partners aim to establish an industrially scalable recycling process that sets new quality standards in mechanical recycling. Process Engineering Innovation The Flexloop system adds an additional extraction step to the established mechanical pre-cleaning process. Using solvents, impurities, organic residues, and odor-causing substances are removed from plastics without altering the polymer structure. The modular system can be integrated into existing Lindner washing and recycling plants, significantly improving the quality of recyclates. Improved Recyclate Quality and New Application Opportunities According to Lindner, the process is particularly suitable for plastic streams from post-consumer collections, which are often contaminated or mixed with various materials. Until now, such recyclates were mainly used for low-grade applications. With Flexloop, recyclers can now produce materials that meet the high standards of brand manufacturers. This enables their use in high-quality packaging, contributing to the closure of the material loop. Economic and Environmental Benefits Compared to chemical recycling, Flexloop is said to offer lower investment and operating costs. The technology provides mechanical recyclers with a cost-effective retrofit solution to expand existing systems and enhance material quality. Procter & Gamble highlights the technology’s contribution to reducing plastic waste and promoting a functional circular economy. With the introduction of Flexloop, Lindner and Procter & Gamble present a new approach to improving quality in mechanical recycling. The technology combines proven mechanical processes with an innovative solvent-based cleaning step, opening up new perspectives for high-quality plastic recyclates and their use in demanding applications. K 2025, 08.-15. Oktober 2025, Düsseldorf, Germany More information: www.lindner.com, de.pg.com |

Lindner-Recyclingtech GmbH, Spittal an der Drau, Austria

back to news list back to news list |  back to top back to top |