plasticker-News

| 2007-03-05 |

|

Coperion Werner & Pfleiderer: Melt pump for polyolefin lines of own design

|

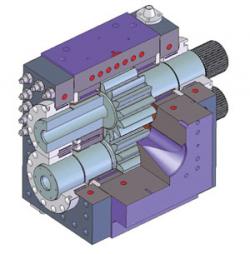

After 1 ½ years´ development and preparation, Coperion Werner & Pfleiderer & Co. KG (www.coperion.com) is now equipping its well-proven twin-screw compounder (ZSK) with melt pumps of its own design. Depending on design and layout and range of products, a polyolefin compounding and pelletizing line may require a melt pump to build up the pressure for the melt filtration and pelletizing processes with particularly low energy input. The new Coperion Melt Pump (CMP) now bridges a gap in the production line that had hitherto existed downstream of the polymer melting and homogenizing processes: Coperion Werner & Pfleiderer now covers the entire process chain from melting to pelletizing with equipment of its own. And in order to maintain the high standard of quality associated with its name, Coperion Werner & Pfleiderer manufactures the core components of the melt pumps in its own production facility. Three Coperion Melt Pumps have already been sold. The first one was successfully put into service by a Russian customer. It will be used in conjunction with a ZSK extruder in an HDPE line with an output rate of 33 tonnes/hour. The same customer will be receiving a second line around the middle of 2007, again with a ZSK extruder and a Coperion Melt Pump. The third Coperion Melt Pump is being used by a South American customer for the purpose of increasing the output rate of an existing ZSK extruder by 20%. This cost-effective solution is possible because the main drive of the ZSK has sufficient power reserves for an increase in screw speed. As energy input into the melt is lower when using a melt pump for pressure build-up, the temperature of the melt remains below the given limit. The Coperion Melt Pump has been engineered according to a well-known and proven concept: a pair of gears with straight involute toothing rotates in polymer-lubricated hydrodynamic bearings. These components are enclosed in a housing and sealed against the outside by threaded shaft seals installed in cover plates mounted on either side of the housing. The technical design – e.g. the type of cooling system and the gear clearance – is rated and determined according to the actual application and product. The melt pump is optionally available with either a single or double shaft drive featuring approved components. Despite Coperion Werner & Pfleiderer´s own melt pump development and manufacture, the gear pump specialist Maag Pump Systems Textron AG, Zürich, will still remain the company´s strategic partner when it comes to the supply of melt pumps for world-scale production lines that already have to meet output requirements of up to 80 tonnes/hour. Moreover, many operators of such high-capacity compounding lines basically demand components that have been approved by the licensor. Photo: 3-D cutaway drawing of Coperion Melt Pump (schematic) |

Coperion Werner & Pfleiderer GmbH & Co. KG, Stuttgart

back to news list back to news list |  back to top back to top |