plasticker-News

| 2012-01-23, 06:01 |

|

DuPont: New grade of low friction, low wear acetal resin for the healthcare industry

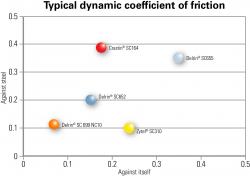

Image: courtesy of Ypsomed. A new, ultra low-friction grade of acetal resin, DuPont™ Delrin® SC 699, which is supplied with extensive regulatory compliance for use in healthcare applications, has been specified by Ypsomed AG (Burgdorf, Switzerland) for a key component of its UnoPen™ disposable injector pen.  Image: DuPont. The new grade of acetal resin, DuPont™ Delrin® SC 699, offers predictable performance and avoidance of excessive friction, stick-slip effects, squeaking where two surfaces slide, roll or rub against each other. The UnoPen™ from Ypsomed AG, a leading independent developer and manufacturer of injection systems, is a state-of-the-art disposable pen designed for the manual injection and delivery of insulin or other drugs from a pre-filled glass cartridge. A principal feature of the device is its ease-of-use based on a well-proven ´dial and inject´ handling concept, in which the dose dial sleeve - the component moulded from Delrin® SC699 acetal resin and located between the housing and the piston rod - plays a key role. It is used by the patient to set the required dose of insulin to be injected and interacts mechanically with the piston rod to dispense the required dosage. "The friction properties of Delrin® SC699 acetal resin used for the dose dial sleeve are fundamental to the pen´s ease of use. If friction between the parts of the pen is kept to its minimum, then the patient will need a minimum of force to dose or inject the drug," explains Stefan Burren, manager product development at Ypsomed. "We tested many polymers that are currently available on the market for this component, but none fulfilled the requirements as well as the DuPont material." Delrin® SC699 acetal resin has been modified for exceptional low friction performance and is suitable for high volume manufacture. It has been specifically developed for parts requiring high precision moulding in the healthcare industry and is supplied with the relevant regulatory compliance (FDA and EU food compliance, production according to GMP standards, testing against USP Class VI and ISO 10993–5 and -11). Further attributes of the new grade leading to its specification for the dose dial sleeve include its compatibility with laser marking, by use of an appropriate masterbatch, for indication of the dose settings. As with other grades from the Delrin® product family, the material also exhibits outstanding properties in terms of strength and stiffness, permitting the snap-fit assembly of the component, as well as ensuring reliable and durable mechanical performance in use. DuPont: Material supplier to the health care segment DuPont offers one of the broadest portfolios of engineering plastics and thermoplastic elastomers for medical devices, surgical devices and for diagnostic or pharmaceutical manufacturing equipment. They offer benefits including structural properties with lower material density and ease of forming geometrically complicated parts. In addition, minimal finishing operations, rapid production cycles, and longer life with enhanced durability all contribute to cost savings. The DuPont health care product offering provides food agency compliance, ISO 10993-5 and -11 compliance as well as USP Class VI compliance. Speciality health care products are manufactured following GMP. Beyond material supply, DuPont actively supports customers with assistance in material selection, tool design and moulding optimization. More Information: www.dupont.com Pharmapack 2012, February 15-16, 2012, Paris, Stand 561 More information: www.dupont.com |

DuPont de Nemours International Sarl., Genf, Schweiz

back to news list back to news list |  back to top back to top |